SHKL has been a leading manufacturer of bathroom vanity, shower doors, and LED bathroom mirrors since 2004.

Are Frameless Shower Doors Safe? Here's What You Should Know

Conclusion(Answer The Question First.)

Briefly: Frameless shower doors are safe overall — provided that they use tempered (toughened) safety glass in compliance with local safety standards, use certified hardware, and are installed and maintained by qualified professionals. The key factors are whether the materials are properly certified/marked and whether installation & maintenance are carried out correctly. (CPSC 16 CFR 1201)

1) Why Frameless Shower Doors Are Popular & A Brief History of Shower Doors

Reasons for popularity:

Minimal aesthetic: frameless designs have clean lines and visual transparency, which is highly desirable in modern bathrooms.

Easier to clean: fewer metal frames and joints, fewer nooks for limescale/mold.

Makes space feel larger: the glass without bulky framing gives a more open feel.

High customizability: panel sizes, glass thickness, hinge/handle styles are flexible.

Brief historical timeline:

Early stage (20th century, early): framed aluminium/metal glass doors dominated—glass panels were held within full metal frame structures.

Mid stage: semi-frameless / narrow-frame designs emerged—narrow metal frames + thinner glass, a compromise between cost and aesthetics.

Recent ~20 years: improvements in manufacturing of large tempered glass panels and heavy-duty metal hardware (stainless steel, brass) enabled the true “frameless” single‐panel or multi‐panel large glass shower doors, making this style mainstream.

(The driver is both aesthetics & manufacturing/engineering progress.)

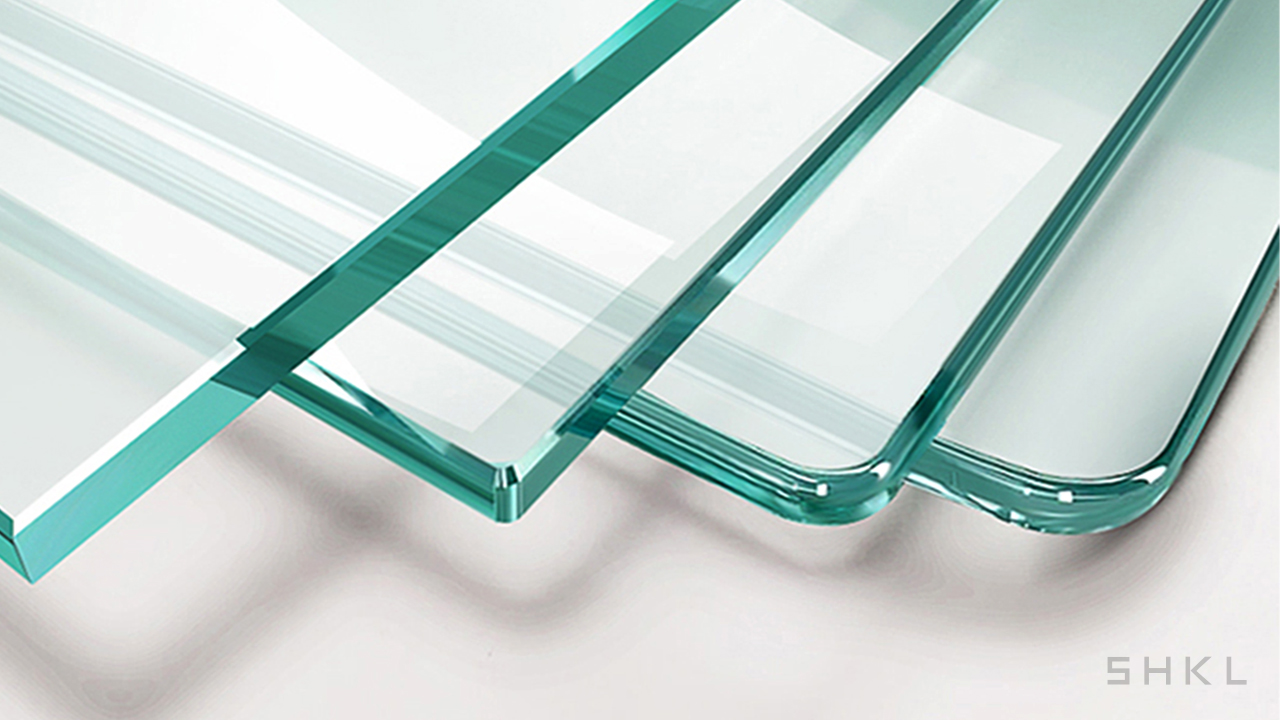

2) Material for Frameless Shower Doors: Tempered (Toughened) Safety Glass — What about its safety?

Key points:

How tempered glass works: The glass is heated to a high temperature then rapidly cooled, producing surface compressive stress and internal tensile stress. This treatment raises the strength of the glass about 4–5× compared to annealed (ordinary) glass; when it breaks, it fragments into many small granular pieces with dull edges, reducing the risk of deep cut injuries.

Standards/regulations requiring safety glass: In many regions, glass elements used in shower doors/bath doors must meet safety glass standards (e.g., USA: CPSC 16 CFR 1201 / ANSI Z97.1; Europe: EN 12150; Australia/NZ: AS/NZS 2208 / AS 1288). That means suppliers who certify compliance are required. (CPSC 16 CFR 1201)

Special note on “spontaneous breakage”: A rare cause is nickel‐sulfide (NiS) inclusions in tempered glass manufacturing, which under certain thermal conditions can lead to spontaneous breakage (without apparent external impact). This risk is low, and the industry uses “heat-soak testing” to reduce it. Overall, tempered glass remains much safer than ordinary glass.

3) Common Safety Issues with Frameless Shower Doors

Glass breakage/fracture — caused by impact, edge damage, NiS inclusion, thermal shock. When it breaks, while small‐piece safety glass is safer than large shards, there is still risk of injury or slipping.

Hinge or fixing hardware failure or incorrect installation — causes: loose bolts, poor substrate/wall anchor, wrong expansion fastener; risk: panel detachment or collapse.

Poor edge or cut finish on glass — if edge isn’t polished or has micro‐cracks, cracks can propagate easily from the edge (edges are stress concentrators).

Water leakage/slip hazard — frameless doors often have weaker sealing; if drainage is inadequate water can spill out, creating a wet and slippery floor, increasing fall risk.

Pinch points — hinges or door gaps may create pinch hazards, especially for children or older people.

Corrosion or aging of hardware — especially in coastal or humid environments; if hardware is not 304/316 stainless or properly treated, corrosion can weaken supports.

(Most incidents aren’t because frameless doors are inherently “dangerous”, but because materials are sub‐par, thickness insufficient, or installation & maintenance negligent.)

4) How to Prevent Accidents & Safety Maintenance Notes (Practical Checklists)

Before purchase & installation:

Ask to see or obtain test certificate / conformity declaration (e.g., “meets ANSI Z97.1 / CPSC 16 CFR 1201” in the USA; equivalent in other regions). (CPSC 16 CFR 1201)

Choose appropriate glass thickness: typically for frameless shower doors: 8 mm (5/16″) or 10 mm (3/8″); larger unsupported panels may require 12 mm (1/2″).

Hardware specs must match glass thickness; opt for trusted brands and ensure corrosion resistance (e.g., 304/316 stainless steel, anodized, etc.).

During installation:

Use installation by a qualified glass/shower installer following proper anchors, level check, hinge torque settings.

If adjacent to heat source or subject to thermal stress, inform installer.

Consider soft‐close hinges or dampers if possible to reduce impact loads.

Daily use & maintenance (suggested periodic tasks):

Monthly visual inspection: check for micro‐cracks at edges, hinge screws, hardware corrosion, seal strip condition.

If you spot any micro‐crack/edge chip: do not wait—replace or consult installer. Cracks propagate quickly under stress.

Keep seal strip intact to prevent water leak → slip risk.

Avoid striking glass with hard/sharp objects; use soft cloth + neutral cleaner—no abrasive scourers.

If you have children or seniors at home: consider adding a transparent protective film (“safety film”) over the glass or use doors with further safety features (extra film lamination) as an extra safeguard.

5) Frameless vs Framed Shower Doors: Which One Is Safer?

Framed doors advantages: The frame provides edge support, allowing thinner glass (e.g., 4–6 mm) and in some impact scenarios the frame may absorb loads, so in theory the probability of “whole‐pane failure” may be lower.

Frameless doors advantages: Typically use thicker glass (8–12 mm) and heavy‐duty hinges/clamps; fewer frame seams means fewer weak points and fewer places for corrosion or seal failure; visually more open.

Overall judgment: When materials are certified + installation is proper, both types can be very safe. But if materials or installation are substandard, frameless may carry higher risk simply because the glass is often larger/unsupported and the consequences of failure may be more dramatic.

If you want maximum “safe bet” and lower maintenance burden: a well‐designed framed/semi‐framed door might be slightly more conservative.

If you are committed to using thick tempered glass, robust hardware and expert installation: frameless can deliver equal safety + superior aesthetics.

In short: Not the style alone, but rather “materials + installation quality” determine safety.

6) How to Buy a Certified Shower Door in North America / Australia / Europe — What Certifications to Look For & How to Verify

North America (USA/Canada)

Key standards/regulations:

CPSC 16 CFR Part 1201: U.S. Consumer Product Safety Commission regulation for building‐use safety glazing materials (includes bath/shower doors). (CPSC 16 CFR 1201)

ANSI Z97.1: American National Standard for Safety Glazing Materials — marking, testing, performance. (ANSI blog about Z97.1)

How to purchase/verify: On the product page or label check for “Meets ANSI Z97.1 / CPSC 16 CFR 1201”. Request manufacturer’s test report or Certificate of Compliance. Large retailers often mark “ANSI Certified”. (Home Depot ANSI Certified listing)

Australia / New Zealand

Key standards:

AS/NZS 2208 (Safety glazing materials in buildings)

AS 1288 (Glass selection & installation) — a frequently referenced standard for shower screens and shower doors. (Testing standards doc)

How to purchase/verify: Supplier should provide a conformity certificate referencing AS/NZS 2208, confirm grade (e.g., Grade A toughened/laminated safety glass) and installation must comply with AS 1288. (AGG Australia shower screens product page)

Europe (EU/UK)

Key standards/regulations:

EN 12150 (Thermally toughened safety glass) — ensures mechanical/fragmentation behaviour of tempered glass. (What is EN12150?)

EN 14428 (Shower enclosures performance requirements and test methods) — applicable to shower screens/doors as part of shower enclosure fittings.

CE Marking / Declaration of Conformity (DoC): Where applicable, the product must bear CE mark and be accompanied by DoC showing compliance with the relevant EU directive/standards. (CE marking of glass explanation)

How to purchase/verify: Check for the EN standard numbers on the product label, ask for the manufacturer’s DoC, request third-party test report or “Notified Body” certification if required. (CE marking explanation doc)

Practical Buyer/Verification Checklist

- Check if the glass corner or panel is labelled / etched with a standard mark (e.g., EN12150, ANSI Z97.1, etc.). (ANSI marking blog)

- Ask the seller for the third‐party test report (lab certificate) or Certificate of Conformity. (Safety glass quick reference guide)

- Check hardware material specification: is it 304/316 stainless, or plated/treated to resist corrosion? (Especially for coastal regions.)

- Confirm the glass thickness is appropriate for the size of the door/panel (see guideline: e.g., 8mm minimum for frameless smaller panels).

- Get installation instructions and ensure installation is done by a qualified specialist; retain proof of warranty/install certificate.

Final Practical Advice (for your B2B context)

Since you are targeting B2B customers (importers, distributors, agents, large supermarkets) with your brand and product lines: include in your procurement specifications “must comply with local region’s safety glass standards and provide third‐party test reports” as a mandatory clause.

References and Key Sources (for quick review)

U.S. Regulation: CPSC 16 CFR Part 1201 (shower/bathtub doors fall under this category of architectural glazing materials). Legal Information Institute

ANSI Z97.1: U.S. Safety Glazing Standard Explanation. The ANSI Blog

Europe: EN 12150 (tempered glass), EN 14428 (performance for shower enclosures/partitions), and CE marking requirements. abc Glass Processing+2showerglasshardware.com+2

Australia/New Zealand: AS/NZS 2208, AS 1288 (standards for safety glass and installation). Environmental Chambers+1

Nickel Sulfide (NiS) and Spontaneous Breakage Technical Information: explanation of causes and heat-soak testing method. pilkington.com+

Get In Touch With SHKL

Contact Person: Rita Luo

E-mail: info@shklbathroom.com

E-mail: info@shkl.cc

Tel: +86 0757 82583932

Fax: +86 0757 82583936

Whatsapp: +86 139 299 10217

Foshan SHKL Sanitary Ware Co., Ltd.