SHKL has been a leading manufacturer of bathroom vanity, shower doors, and LED bathroom mirrors since 2004.

Tempered vs. Laminated Glass for Shower Doors — which is better?

Conclusion (brief answer)

Short answer up front: Both are “safety” glasses but they behave very differently. Tempered glass is the usual, lower-cost choice for shower doors (it crumbles into small pebble-like pieces when it fails). Laminated glass is glass + a plastic interlayer (PVB, SGP, EVA) so if it’s hit it may crack but the fragments stay stuck to the interlayer — giving better post-break containment and extra benefits (sound reduction, security, UV control). Which is “better” depends on your priorities: budget and simplicity → tempered; maximum protection for kids/elderly, security, or where fragmentation containment matters → laminated.

What is tempered (toughened) glass?

Tempered glass is soda-lime glass that has been heat-treated (rapid cooling) to create surface compression and internal tension — that makes it much stronger in bending and impact than ordinary annealed glass and causes a safer break pattern. Tempered glass used in doors and enclosures is commonly required to meet regional safety glazing standards (e.g., CPSC 16 CFR Part 1201, ANSI Z97.1 in the U.S.; EN 12150 in Europe; AS/NZS 2208 in Australia/NZ). eCFR+1

What happens when tempered glass breaks?

Because of the internal stresses, tempered glass does not split into long, razor shards. Instead it typically crumbles into many small, relatively blunt “dice” or pebble-like fragments. That greatly reduces the chance of deep lacerations compared with annealed glass — which is why tempered glass is specified for shower doors. Fab Glass and Mirror+1

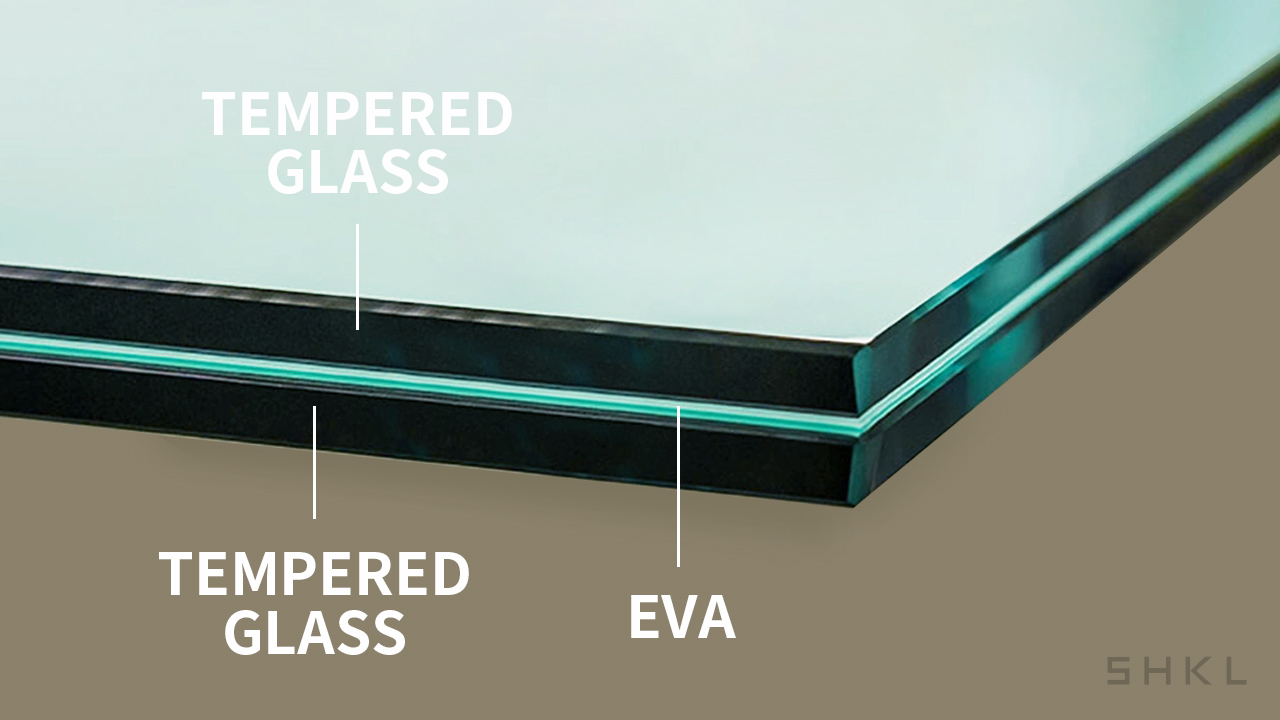

What is laminated glass?

Laminated glass is two or more lites of glass permanently bonded with one or more plastic interlayers (common interlayers: PVB, SGP/SentryGlas, EVA). The interlayer holds the glass fragments in place if the glass fractures, so the assembly acts together after breakage and resists penetration. Laminated glass is covered by standards such as EN 14449 / ISO 12543 in Europe and related product standards elsewhere. interglassusa.com+1

What happens when laminated glass breaks?

When laminated glass is hit hard, the outer glass panes crack or shatter, but the interlayer keeps the pieces bonded, preventing large pieces from flying away and often preserving some barrier function (you can still see through the cracked panel, and it often still holds as a “screen”). This containment behavior is why laminated glass is used where human impact containment or intrusion resistance is needed. www.shklbathroom.com

Quick pros & cons (at-a-glance)

Tempered glass

Pros: Lower cost, lighter than laminated of equal thickness, excellent clarity, common and widely available, meets standard safety specs, simpler fabrication.

Cons: When it fails it fully disintegrates (no remaining barrier); offers no extra sound reduction or UV control; less post-break protection.

Laminated glass

Pros: Holds shards in place after break, better post-break safety (less chance of falling shards), better sound insulation, can include UV control or decorative interlayers, can use stronger interlayers (SGP) for high durability.

Cons: Higher cost, slightly heavier, more complex manufacturing, small risk of edge delamination over long service life if not well manufactured/installed, slightly lower optical purity with some interlayers/ages. stevenage-glass.co.uk+1

Side-by-side comparison by key dimensions

| Dimension | Tempered glass | Laminated glass |

|---|---|---|

| Safety (impact + cut risk) | High (crumbles into small pieces) but no barrier after break. | Very high — fragments held in place; maintains a barrier and reduces hazard. (Fab Glass and Mirror) |

| Durability (wear & weather) | Very durable; low risk of long-term edge issues if installed correctly. | Durable, but edge delamination or interlayer aging is a possible long-term issue if moisture/chemicals reach the interlayer; higher grades (SGP) last longest. |

| Cost | Lower (most common, simpler). | Higher — price premium for lamination, interlayer choice (PVB vs SGP), and processing. |

| Weight | Lighter (single lite). | Heavier (two or more lites + interlayer). |

| Breakage behavior | Full shatter into many small pieces — no containment. (Fab Glass and Mirror) | Cracks but pieces stay bonded to interlayer — often remains functional as a barrier. |

| Optics (clarity) | Excellent. | Excellent for quality laminates, but some interlayers (or aged EVA/PVB) can yellow or show slight haze over decades. |

| Sound insulation | Lower. | Better (interlayer damps sound). |

| Maintenance / repair | Low — usually replace entire panel if damaged. | Low to moderate — often still safe after cracking; may require resealing if edge issues or delamination occur. |

Maintenance and long-term costs

Tempered glass: little routine maintenance beyond cleaning and checking seals/hinges. If broken, the panel must be replaced.

Laminated glass: routine cleaning and seal maintenance are important (especially at edges). Over decades, inferior laminates or poor edge finishing can lead to delamination, clouding, or small bubbles; these issues increase maintenance/repair/replacement cost. High-quality laminated glass made with durable interlayers (e.g., SGP) and correct edge sealing will minimize these risks and extend life. Overall, laminated may cost more up front and — depending on quality/installation — may incur slightly higher long-term maintenance if delamination problems arise.

Common laminated-glass problems (what to watch for)

Delamination (edge or overall): moisture or contaminants penetrating the edge or poor lamination process causes the interlayer to separate or form bubbles. Proper edge sealing and quality lamination reduce this risk.

Yellowing/clouding: some interlayers (especially EVA or low-grade PVB) can discolor under UV/moisture over many years. Use UV-stable interlayers for long life. gdmglass.com

Weight & hardware: laminated panels are heavier — confirm hinges, tracks, and framing are rated for the load.

Cost sensitivity: laminated is more expensive; verify the supplier’s manufacture/QA records and warranty.

Is laminated glass waterproof?

Glass itself is impermeable, but the laminate assembly can be compromised at edges if not properly sealed — water or steam can accelerate edge degradation/delamination in poor installations or with inferior interlayers. In well-fabricated and well-installed laminated shower doors (correct edge polish, sealing, and suitable interlayer), routine shower exposure is normally handled without problems. In short: not inherently “water-leaky,” but quality of fabrication/edge sealing matters.

Lifespan

Tempered glass shower panels: commonly last the lifetime of the installation (20–35+ years) unless damaged by impact, thermal shock (rare if properly specified), or installation issues.

Laminated glass: manufacturer and interlayer type matter. PVB laminates commonly last decades (many sources cite 10–25+ years for standard PVB; advanced interlayers like SGP last longer and resist delamination). With good materials and installation you can expect laminated units to last multiple decades; lower-quality laminates or poor installations shorten life.

Which is best for children or elderly?

If maximum post-break containment and reduced risk from falling shards is the priority (e.g., homes with small children, elderly users who may slip), laminated glass is the better option because it holds broken glass in place and often preserves a physical barrier after impact. Tempered glass is still “safety glass” (it reduces laceration risk compared to annealed glass) but it completely disintegrates on failure — which could still create a slipping/hazard situation.

Practical recommendations (short checklist)

- If budget and standard safety are primary: choose tempered safety glass that meets local standards (look for markings/certificates: CPSC 16 CFR 1201, ANSI Z97.1, EN 12150, AS/NZS 2208). eCFR+1

- If extra safety (containment), sound reduction, or security is important (kids, elderly, glass near floor, high-traffic bathrooms): choose laminated glass with a high-quality interlayer (PVB for typical use; SGP for longer life/greater stiffness). Make sure edges are properly finished and sealed.

- For wet, high-humidity environments: specify laminates from reputable manufacturers, ask about edge sealing, and prefer interlayers with proven moisture/UV resistance.

- Always verify certifications and marking on the glass and ask the supplier for test/certification documents (tempered/laminated standards mentioned above). eCFR+1

Bottom line

- Tempered glass = most common, cost-effective, meets baseline safety standards (crumbles into small pieces on break). Great for typical shower doors.

- Laminated glass = safer after break (fragments stay bonded), better for houses with kids/elderly or where you want added sound/security/UV control — but costs more and demands careful fabrication/edge sealing to avoid long-term delamination.

If you want, I can:

- write a short buyer’s checklist (questions to ask a glass supplier),

- draft a short comparison table formatted for your product page, or

- search suppliers and interlayer types (PVB vs SGP vs EVA) with price-range examples in your target market — tell me which of those you want and I’ll produce it next.

Get In Touch With SHKL

Contact Person: Rita Luo

E-mail: info@shklbathroom.com

E-mail: info@shkl.cc

Tel: +86 0757 82583932

Fax: +86 0757 82583936

Whatsapp: +86 139 299 10217

Foshan SHKL Sanitary Ware Co., Ltd.